The EVO B back-contact solar modules pioneer the adoption of full-back welding technology to effectively improve the resistance to micro cracking of modules.

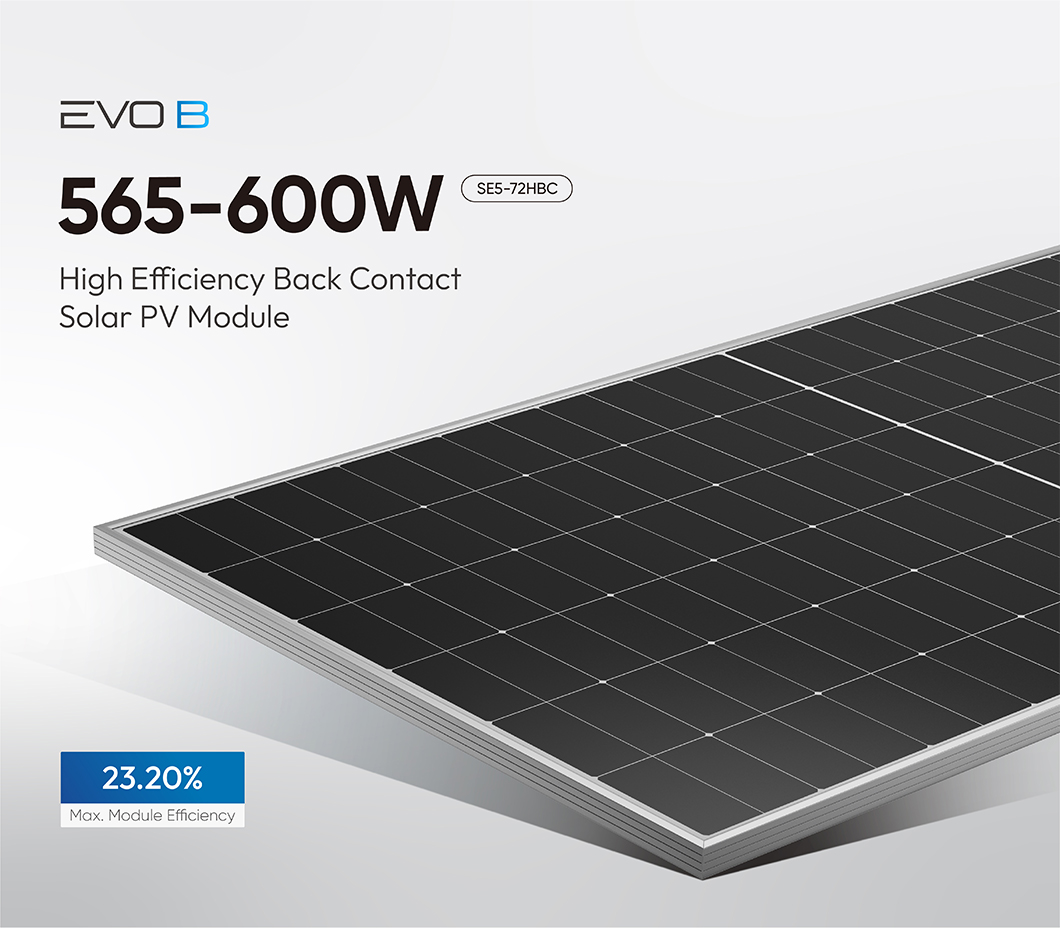

Brand:

SunEvoPower Range:

565W~600WMax. Efficiency:

23.20%Number of Cells:

144 (6×24)Dimensions of Module L*W*H:

2278 × 1134 × 35mmWeight:

27.5kgFront Side Glass:

Single glass, 3.2mm coated tempered glassBacksheet:

backsheetFrame:

Anodized aluminium alloyJunction Box:

Ip68 rated (3 by pass diodes)Cable:

4mm2 , ±1200mm length can be customizedWind/Snow Load:

5400PaConnector:

Mc4 compatibleEVO B High-Efficiency Back Contact Solar PV Module 565W 570W 575W 580W 585W 590W 595W 6000W

The EVO B back-contact solar modules pioneer the adoption of full-back welding technology to effectively improve the resistance to micro cracking of modules.

Electrical Parameters (STC*)

|

Maximum Power (Pmax/W) |

565 |

570 |

575 |

580 |

585 |

590 |

595 |

600 |

|

Maximum Power Voltage (Vmp/V) |

43.61 |

43.76 |

43.91 |

44.06 |

44.21 |

44.36 |

44.51 |

44.66 |

|

Maximum Power Current (Imp/A) |

12.96 |

13.03 |

13.10 |

13.17 |

13.24 |

13.31 |

13.37 |

13.44 |

|

Open Circuit Voltage (Voc/V) |

51.76 |

51.91 |

52.06 |

52.21 |

52.36 |

52.51 |

52.66 |

52.81 |

|

Short Circuit Current (Isc/A) |

14.01 |

14.07 |

14.14 |

14.20 |

14.27 |

14.33 |

14.40 |

14.46 |

|

Module Efficiency (%) |

21.9 |

22.1 |

22.3 |

22.5 |

22.6 |

22.8 |

23.0 |

23.2 |

|

Power Output Tolerance (W) |

0~3% |

|||||||

|

Temperature Coefficient of Isc |

+0.05%/°C |

|||||||

|

Temperature Coefficient of Voc |

-0.23%/°C |

|||||||

|

Temperature Coefficient of Pmax |

-0.29%/°C |

|||||||

The Difference Between Back-Contact and Conventional Components

In the world of electronics and solar technology, there are two primary types of components: back-contact components and conventional components. These two design approaches have important distinctions that impact their performance and applications. In this article, we will explore the key differences between these two types of components.

Back-Contact Components: Back-contact components are designed with the electrical contacts on the rear side of the component, facing away from the incident light. This design minimizes shading, as the front side is entirely dedicated to capturing sunlight.

Conventional Components: Conventional components, on the other hand, have their electrical contacts on the front side, which can result in some shading by the metal conductors and busbars. The front side of conventional components is responsible for both capturing light and transmitting electrical current.

Back-Contact Components: Because the electrical contacts are located on the rear side, back-contact components tend to have lower shading losses. This design allows for more efficient utilization of the entire surface area to absorb sunlight.

Conventional Components: Conventional components can experience higher shading losses due to the presence of front-side electrical contacts. These contacts can obstruct incoming sunlight, reducing the overall efficiency of the component.

Back-Contact Components: Back-contact components often exhibit higher energy conversion efficiencies. With reduced shading and improved light absorption, they can generate more electricity for a given surface area.

Conventional Components: Conventional components, while still efficient, may have slightly lower energy conversion efficiencies compared to back-contact components. Shading and light obstruction can lead to some energy loss.

Back-Contact Components: The manufacturing of back-contact components can be more complex and costly due to the precision required in placing electrical contacts on the rear side of the component. However, this complexity is often offset by improved performance.

Conventional Components: Conventional components are generally easier and less expensive to manufacture, as the front-side electrical contacts are more straightforward to apply. This results in a cost advantage for conventional designs.

Back-Contact Components: Back-contact components are particularly well-suited for applications where space is limited or where shading is a significant concern. They are commonly used in residential solar installations and portable solar devices.

Conventional Components: Conventional components are still widely used in utility-scale solar farms and applications where cost-effectiveness is a primary consideration. Their slightly lower efficiency may be acceptable in these scenarios.

Back-Contact Components: Back-contact components often have a cleaner and more aesthetic appearance from the front, as there are no visible electrical contacts. This makes them a popular choice for residential installations.

Conventional Components: Conventional components may have visible front-side electrical contacts, which can impact their aesthetics. However, this is less of a concern in utility-scale installations.

Both back-contact and conventional components have their advantages and disadvantages, and the choice between them depends on specific project requirements, cost considerations, and aesthetic preferences. Back-contact components excel in situations where shading and efficiency are critical, while conventional components offer cost advantages and are still the preferred choice for many applications. As technology continues to advance, we may see further developments and improvements in both designs, providing even more options for solar energy generation.